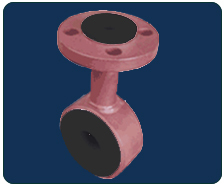

CS HDPE Lined Equal Tee

CS HDPE Lined Equal Tee Specification

- Flexibility

- Rigid

- Connection Type

- Flange ends

- Sealing Type

- Gasket Sealing (recommended with flanges)

- Tensile Strength

- 32 MPa (HDPE Lining)

- Bend Radius

- Equal Tee; no bend

- Tolerance

- 2 mm

- Diameter

- 25 mm to 600 mm

- Yield Strength

- 210 MPa (Carbon Steel body)

- Product Type

- Equal Tee

- Material

- Carbon Steel body with High Density Polyethylene (HDPE) Lining

- Connection

- Flanged

- Shape

- Tee

- Standard

- ASTM / ASME / DIN / EN

- Surface Treatment

- HDPE Lined, Painted Finish

- Outer Diameter

- 25 mm to 600 mm

- Section Shape

- Round

- Length

- Varies based on diameter and standard

- Thickness

- 3 mm to 10 mm (varies by size)

- Color

- Black (HDPE Lining)

- Usage

- Corrosive media transport, chemical process pipe systems

- Rated Pressure

- PN10 / PN16 / ANSI Class 150

- Application

- Pipeline fitting for chemical, pharma & water treatment industries

- Material Grade

- CS ASTM A106/A105 with Virgin HDPE lining

- Service Life

- Up to 25 years under correct conditions

- Lining Thickness

- 3 mm minimum (customizable up to 6 mm)

- Lining Hardness

- 65 Shore D

- Flange Face Type

- Raised Face / Flat Face

- Pipe Ends

- Bevelled or as per customer

- Leak Test Pressure

- 1.5 times rated pressure

- Testing Standard

- Hydrostatic, Spark, and Eddy Current Tests

- Corrosion Resistance

- Excellent; suitable for acids, alkalies & salts

- Weight

- Varies by size; for example, ~15 kg for DN100

- Packing

- Plastic wrap, wooden box or as required

CS HDPE Lined Equal Tee Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Cheque

- Delivery Time

- 2-3 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Packing as per Customer requirement

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO:9001:2008

About CS HDPE Lined Equal Tee

| Dimensional Data : | ||||||||||||||||||||||||||||||||||||||||||||

| | ||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||

Material Specifications and Dimensional Standards:

Flanges: Linning:

|

Robust Corrosion Resistance

With a premium HDPE lining, this equal tee withstands aggressive chemicals, acids, and alkali salts commonly found in process industries. The linings hardness of 65 Shore D and minimum thickness of 3 mm offer robust protection for long-term use in highly corrosive environments, minimizing maintenance and extending service intervals.

Reliable Testing Standards

Each tee is subjected to comprehensive testing including hydrostatic, spark, and eddy current tests. Leak test pressure is maintained at 1.5 times the rated pressure, guaranteeing safety and operational reliability. These tests ensure the product adheres to ASTM, ASME, DIN, and EN standards, making it a reliable solution for critical pipeline systems.

Versatile Packing and Sizing

Offered in diameters from 25 mm to 600 mm and customizable lining thicknesses up to 10 mm, these tees suit diverse pipeline needs. They are packed securely in plastic wrap or wooden boxes, as required, ensuring they reach the installation site in pristine condition. Options for flange face type and pipe ends add to their adaptability.

FAQs of CS HDPE Lined Equal Tee:

Q: How does the HDPE lining benefit the CS HDPE Lined Equal Tee in corrosive environments?

A: The HDPE lining offers excellent resistance against acids, alkalies, and salts, safeguarding the carbon steel body from chemical attack. This results in reduced maintenance, longer operational life (up to 25 years), and reliable performance even when exposed to aggressive chemical media.Q: What is the standard process for testing these tees before dispatch?

A: Each CS HDPE Lined Equal Tee undergoes hydrostatic, spark, and eddy current tests as per international standards. Additionally, a leak test is performed at 1.5 times the rated pressure to ensure structural integrity and safety, meeting ASTM, ASME, DIN, and EN standards.Q: When should the lining thickness be customized, and what options are available?

A: Lining thickness is customized based on the corrosiveness of the media and specific application requirements. The standard minimum is 3 mm, with options to increase up to 6 mm or more (up to 10 mm for certain sizes) to enhance protection in more demanding environments.Q: Where can the CS HDPE Lined Equal Tee be used effectively?

A: These tees are suitable for pipeline systems in chemical processing plants, pharmaceuticals, water treatment facilities, and industries where corrosive media transport is essential. Their adaptability regarding diameter and flange details ensures compatibility across various sectors.Q: What are the connection and sealing types available for this product?

A: The tees are designed with flanged ends (raised face or flat face), accommodating gasket sealing, which is recommended for secure and leak-proof installation. Pipe end preparation can be bevelled or tailored to customer specifications for seamless integration into existing systems.Q: How does the products physical strength contribute to its reliability?

A: With a carbon steel body offering a yield strength of 210 MPa and an HDPE lining tensile strength of 32 MPa, the tee exhibits excellent mechanical durability. This combination provides a rigid and robust solution ideal for high-pressure and corrosive flow applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lined Tees Category

PTFE Lined Lateral Tee

Minimum Order Quantity : 01 Unit

Thickness : Schedule 40 / Customized

Diameter : 25 mm to 300 mm

Section Shape : Round

Tolerance : 1 mm

Length : Customized as per project needs

MS HDPE Lined Equal Tee

Minimum Order Quantity : 01 Piece

Thickness : 4 mm to 12 mm (as per specification)

Diameter : 40 mm to 600 mm

Section Shape : Round

Tolerance : 0.5 mm

Length : As per requirement / standard

PP Lined Instrument Tee

Minimum Order Quantity : 01 Unit

Thickness : 3 mm (PP lining thickness)

Diameter : 1 to 8 (25mm to 200mm)

Section Shape : Round

Tolerance : 1 mm

Length : Customized / Standard (as per design)

HDPE Lined Lateral Tee

Minimum Order Quantity : 01 Unit

Thickness : HDPE lining thickness: 35 mm, Steel body thickness: 510 mm

Diameter : Specified by nominals: 50 mm to 600 mm

Section Shape : Round

Tolerance : 0.5 mm

Length : Based on nominal diameter and standards, typically 250 mm to 600 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS