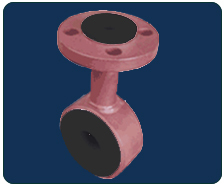

PP Lined Instrument Tee

PP Lined Instrument Tee Specification

- Bend Radius

- As per design specification

- Temperature Range

- -20C to +100C

- Flexibility

- Rigid

- Connection Type

- Flanged

- Yield Strength

- As per MS pipe used

- Diameter

- 1 to 8 (25mm to 200mm)

- Tensile Strength

- 35 MPa (PP lining)

- Sealing Type

- Gasket Seal (PTFE/EPDM gasket as required)

- Coating Type

- Polypropylene Lined

- Tolerance

- 1 mm

- Product Type

- Instrument Tee

- Material

- Polypropylene (PP) Lined with MS outer body

- Connection

- Flanged Ends

- Shape

- T-shaped

- Standard

- ASTM / DIN / IS (as per client requirement)

- Surface Treatment

- Polypropylene Lined

- Outer Diameter

- As per size (generally 1 to 8)

- Section Shape

- Round

- Length

- Customized / Standard (as per design)

- Thickness

- 3 mm (PP lining thickness)

- Color

- Blue / Natural White (Liner)

- Usage

- Chemical transfer, instrumentation lines

- Rated Pressure

- Up to 10 Kg/cm (PN10)

- Application

- Acid & chemical industries, instrumentation, fluid handling

- Material Grade

- Industrial Grade PP lining with MS body

- Weight

- As per size and length

- Testing Standard

- ASTM F1545-15

- Outer Body Material

- Mild Steel (MS) with epoxy coating

- Leak Proof Test

- Hydro tested at 1.5 times rated pressure

- Packing

- Wooden Box or as per customer requirement

- Minimum Order Quantity

- 1 Piece

- Inspection

- Third-party inspection, if required

- Liner Hardness

- 65-70 Shore D

- Manufacturing Method

- Lined in-situ molding process

- Design Code

- As per ASME / DIN standards

- Traceability

- Available as per project needs

- Resistant To

- Acids, Alkalis, Chlorine, Solvents

- Corrosion Resistance

- Excellent against most chemicals and acids

- End Connection

- Drilled to relevant standards

- Flange Standard

- ANSI B16.5 / DIN / IS

- Anti-static Option

- Available on request

PP Lined Instrument Tee Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Cheque

- Delivery Time

- 2-3 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Packing as per Customer requirement

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Western Europe, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO:9001:2008

About PP Lined Instrument Tee

Optimal Applications & Competitive Edge of PP Lined Instrument Tee

PP Lined Instrument Tees excel in acid and chemical industries, instrumentation, and fluid handling lines because of their robust corrosion resistance and rigorous testing standards. Flexible in applicationbe it process piping or transfer linestheir gasket sealing and rigid construction assure zero leakage and operational safety. Clients gain a competitive advantage with the products certified inspection, anti-static options, and adaptability to global standards, ensuring reliability and longevity for industrial use. Supreme quality meets versatile usage across demanding environments.

Sample Availability, Payment Terms & Quotation Drop-off Process

Experience prompt arrival of PP Lined Instrument Tee samples, enabling hands-on evaluation before large orders. Clients can request samples, and quotations are provided swiftly based on specifications and drop-off details shared by the client. Payment terms are transparent, with flexible options available for bulk purchases. Our sample policy ensures that upon acceptance of the quotation, products are dispatched securely, reinforcing trust and facilitating seamless business collaborations. Fast response and clarity in policies enhance your procurement journey.

PP LINED INSTRUMENT TEE

| Dimensional Data : | ||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

|

Material Specifications and Dimensional Standards:

Flanges: Linning:

|

FAQs of PP Lined Instrument Tee:

Q: How is the PP Lined Instrument Tee manufactured and tested for quality?

A: The PP Lined Instrument Tee is produced using in-situ molding with industrial-grade PP lining inside a mild steel body. Each unit undergoes hydrostatic testing at 1.5 times the rated pressure. Additional tests, such as spark, air leak, and vacuum tests, can be conducted as per customer request under ASTM F1545-15 standards.Q: What are the main applications of the PP Lined Instrument Tee?

A: This instrument tee is ideal for acid and chemical industries, fluid handling, and instrumentation lines. Its corrosion-resistant lining makes it suitable for safely transferring aggressive chemicals, alkalis, solvents, and chlorine under demanding conditions.Q: Where can I use the PP Lined Instrument Tee in my facility?

A: The PP Lined Instrument Tee can be integrated into process piping networks, chemical dosing systems, instrumentation branches, and fluid distribution setupsanywhere robust resistance to acids and chemicals is required.Q: What payment terms and sample policy does your company offer?

A: We provide samples upon request with a clear quotation process. Payment terms are communicated transparently, and flexible arrangements can be made for bulk or repeated orders. Samples arrive promptly to allow for product evaluation.Q: What benefits does the anti-static option provide?

A: The anti-static option ensures enhanced safety by preventing electrostatic charge build-up, critical when handling volatile chemicals. This feature is available on request to further comply with process safety requirements.Q: How can I trace the origin and inspection status of my order?

A: Traceability features are integrated into production. Third-party inspection reports can be provided if required, and all documentation is available to ensure every product meets project-specific needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lined Tees Category

HDPE Lined Lateral Tee

Minimum Order Quantity : 01 Unit

Connection Type : Flanged, Butt welded, Screwed

Product Type : Other, Lined Lateral Tee

Standard : Other, ASTM D3350 / IS 4984

Application : other, Chemical, Petrochemical, Water Treatment Plants, Effluent Handling

Material : Other , Carbon Steel body with HDPE lining

HDPE Lined Unequal Tee

Minimum Order Quantity : 01 Unit

Connection Type : Welded or Flanged Ends (as required)

Product Type : Other, HDPE Lined Unequal Tee

Standard : Other, ASTM D3350, ASME B16.9

Application : other, Chemical Industry, Water Treatment Plant, Oil & Gas

Material : Other , Carbon Steel with HDPE Lining

PP Lined Equal Tee

Minimum Order Quantity : 01 Unit

Connection Type : Flanged Connection

Product Type : Other, Equal Tee

Standard : Other, ASTM / DIN / IS

Application : other, Acids, Alkalis, Corrosive Fluids

Material : Other , PP (Polypropylene) lined steel

PP Lined Unequal Tee

Minimum Order Quantity : 01 Unit

Connection Type : Flanged

Product Type : Other, PP Lined Unequal Tee

Standard : Other, DIN 16962 / ASTM F1545 / ANSI B16.5

Application : other, Acid handling, corrosive chemical conveyance

Material : Other , Polypropylene (PP) Lined with MS/CS body

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS