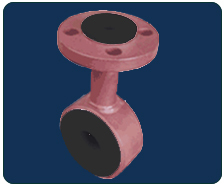

MS HDPE Lined Equal Tee

MS HDPE Lined Equal Tee Specification

- Connection Type

- Welded / Flanged

- Flexibility

- Rigid

- Sealing Type

- Fusion bonded HDPE lining

- Tensile Strength

- 350 MPa (MS base material)

- Coating Type

- HDPE lining & external paint

- Bend Radius

- Conforms to piping design; 90 branch

- Yield Strength

- 250 MPa (MS base material)

- Tolerance

- 0.5 mm

- Diameter

- 40 mm to 600 mm

- Temperature Range

- -20C to +70C

- Product Type

- Equal Tee

- Material

- Mild Steel (MS) with HDPE lining

- Connection

- Butt Weld / Flanged

- Shape

- Tee

- Standard

- ASTM / IS standard

- Surface Treatment

- Painted / Anti-corrosive coating

- Outer Diameter

- 40 mm to 600 mm (customizable)

- Section Shape

- Round

- Length

- As per requirement / standard

- Thickness

- 4 mm to 12 mm (as per specification)

- Color

- Black exterior, Blue HDPE lining

- Usage

- Liquid & chemical transportation

- Rated Pressure

- PN10 / PN16 / PN20

- Material Grade

- IS 2062 MS with virgin HDPE lining

- Application

- Chemical Industries, Water Treatment, Effluent Handling

- Available Customization

- Size, flange drilling, color, lining thickness

- Conductivity

- Non-conductive, suitable for chemical duty

- Weight

- Varies by diameter and thickness (approx. 5kg70kg)

- Life Expectancy

- 10+ years in normal operating conditions

- Packing

- Standard export-worthy packing

- Inner Lining Thickness

- 3 mm to 6 mm (HDPE)

- Manufacturing Process

- Extruded HDPE lining, fabricated steel tee

- End Finish

- Beveled or flanged as per specification

- Leak Proof Test

- Hydrostatic tested upto rated pressure

- Maintenance

- Minimal; easy to clean HDPE inner surface

- Corrosion Resistance

- Excellent due to HDPE lining

- Compliances

- ISO 9001:2015 certified manufacturing

MS HDPE Lined Equal Tee Trade Information

- Minimum Order Quantity

- 01 Piece

- Payment Terms

- Cheque

- Delivery Time

- 2-3 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Packing as per Customer requirement

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO:9001:2008

About MS HDPE Lined Equal Tee

Among the noteworthy enterprises in this domain, our organization is occupied in offering a qualitative assortment of MS HDPE Lined Equal Tee. The offered tee finds its extensive use in industrial and commercial plumbing systems to split or combine the flow of corrosive fluids. This tee is manufactured by our adept professionals using exceptional quality mild steel and high density polyethylene polymers with the aid of innovative techniques. Beside this, the provided MS HDPE Lined Equal Tee can be availed from us in different specifications at industry leading prices.

Features:

-

Easy installation

-

Durability

-

Corrosion resistance

-

Dimensional accuracy

Superior Corrosion Resistance and Longevity

The extruded HDPE lining inside each MS Equal Tee provides remarkable protection against corrosive chemicals and solutions. This minimizes frequent replacement and extends service life beyond ten years under normal operation, making it an excellent choice for demanding industrial environments.

Customizable for Diverse Applications

Manufactured to ASTM and IS standards and ISO 9001:2015 certified, the MS HDPE Lined Equal Tee can be tailored for specific needs. Customization options include sizing from 40 mm to 600 mm, flange drilling, lining thickness, and color, ensuring compatibility with a variety of piping systems.

Engineered for Reliable and Leak-Proof Performance

Each tee undergoes rigorous hydrostatic testing up to its pressure rating (PN10/16/20), guaranteeing a leak-proof seal. The rigid, non-conductive structure is designed for precision (+/- 0.5 mm tolerance) and easy maintenance, allowing for safe, efficient liquid and chemical transport.

FAQs of MS HDPE Lined Equal Tee:

Q: How is the HDPE lining applied to the MS Equal Tee?

A: The HDPE lining is extruded and fusion bonded to the inner surface of the mild steel tee during fabrication, ensuring seamless coverage and strong adhesion for excellent corrosion resistance.Q: What are the typical applications for this HDPE lined equal tee?

A: This product is commonly used for transferring corrosive chemicals, water treatment, effluent handling, and in other chemical industry applications where durability, leak-proofing, and chemical resistance are crucial.Q: When should I choose a beveled end versus a flanged end finish?

A: Beveled ends are selected when the tee will be welded directly into a pipeline, while flanged ends are preferred for systems requiring easier assembly, disassembly, or maintenance.Q: Where can these tees be installed for optimal performance?

A: Install them in pipelines handling corrosive liquids or chemicals, such as in chemical factories, water treatment facilities, or effluent systems, where both internal lining and external anti-corrosive coating ensure longevity and safety.Q: What maintenance does the HDPE lined tee require during operation?

A: Minimal upkeep is necessary; the HDPE inner lining is smooth and easy to clean, effectively resisting residue buildup. Routine visual checks and cleaning help maintain optimal flow and performance.Q: What are the benefits of using a fusion bonded HDPE lining in comparison to other lining methods?

A: Fusion bonding ensures a seamless, leak-proof layer that adheres tightly to the steel substrate, offering superior mechanical strength, chemical resistance, and a longer service lifespan compared to non-bonded linings.Q: How do I customize the tee for my specific piping project?

A: You can specify size (40 mm600 mm), flange drilling pattern, HDPE lining thickness (3 mm6 mm), external color, and connection type (welded or flanged). Customizations ensure the tee matches your design and operational requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lined Tees Category

MS PTFE Lined Equal Tee

Minimum Order Quantity : 01 Piece

Shape : Other, Tee

Rated Pressure : PN10 / PN16 / 150# / 300#

Standard : Other, ASTM / ASME / DIN / ISO

Diameter : 25 mm to 600 mm (NB)

Tolerance : 1 mm

PP Lined Instrument Tee

Minimum Order Quantity : 01 Unit

Shape : Other, Tshaped

Rated Pressure : Up to 10 Kg/cm (PN10)

Standard : Other, ASTM / DIN / IS (as per client requirement)

Diameter : 1 to 8 (25mm to 200mm)

Tolerance : 1 mm

HDPE Lined Unequal Tee

Minimum Order Quantity : 01 Unit

Shape : Other, Tee (Unequal/Reducing)

Rated Pressure : Up to 10 bar

Standard : Other, ASTM D3350, ASME B16.9

Diameter : Main: 75 mm, Branch: 50 mm (customizable)

Tolerance : 1 mm

HDPE Lined Lateral Tee

Minimum Order Quantity : 01 Unit

Shape : Other, Tee (Lateral)

Rated Pressure : PN 10, PN 16 up to 10 bar

Standard : Other, ASTM D3350 / IS 4984

Diameter : Specified by nominals: 50 mm to 600 mm

Tolerance : 0.5 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS