MS HDPE Lined Non Return Valve

MS HDPE Lined Non Return Valve Specification

- Valve Type

- Swing Check Valve

- Features

- Corrosion resistant, leak proof, maintenance free

- Material

- Mild Steel (MS) body with HDPE lining

- Valve Size

- 25 mm to 300 mm

- Control System

- Manual

- Connection Type

- Flanged end

- Sealing

- HDPE Lined, gasketed

- Structure

- Swing type, one way flow

- Application

- Corrosive chemical, acid, and process fluid handling

- Type

- Non Return Valve

- Power

- Manual operation

- Pressure

- Max 10 kg/cm

- Media

- Liquids, chemicals, acids

- Port Size

- As per valve size

- Temperature

- up to 80C

- Disc

- HDPE/PP Lined disc

- Pin

- Stainless Steel

- Body Finish

- Epoxy coated

- End Connection Standard

- ANSI, DIN, BS

- Seat

- HDPE lined, resilient

- Service Life

- Long, suitable for harsh chemical environments

- Installation Orientation

- Horizontal

- Leakage Class

- Class VI, bubble tight when closed

- Operating Instruction

- Install with flow arrow in direction of process flow

- Lining Thickness

- 3-5 mm HDPE lining

- Face to Face Dimension

- As per DIN/ANSI standards

MS HDPE Lined Non Return Valve Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Cheque

- Delivery Time

- 2-3 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Packing as per Customer requirement

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO:9001:2008

About MS HDPE Lined Non Return Valve

Technical Specification

| Material | Stainless Steel |

| Colour | Silver |

| Inner Diameter (Millimeter) | 3.05, 3.2, 4.4, 3.5 |

| Flange Diameter (Millimeter) | 88, 118, 151, 48, 69 |

| Condition | New |

| Valve Size | DN 25,DN 40, DN 50, DN 65, DN 80, DN 100, |

Advanced Corrosion Resistance for Demanding Applications

This valves MS body features a 3-5 mm HDPE lining and a high-performance epoxy finish, offering robust protection against highly corrosive chemicals, acids, and aggressive process fluids. The design ensures durability even under challenging conditions, minimizing corrosion and extending operational life.

Optimized for Reliability and Leak Prevention

Engineered with a Class VI leakage specification, this non-return valve provides bubble-tight sealing when closed. The resilient HDPE lined seat and gasketed HDPE/PP disc ensure leak-proof performance, making the valve ideal for sensitive and hazardous media transfer.

Easy Installation and Compliance with Global Standards

The valve design adheres to leading industry standards (ANSI, DIN, BS), ensuring compatibility and straightforward installation in horizontal orientations. Flanged end connections and a swing-type structure facilitate seamless fitment and versatility across various pipeline configurations.

FAQs of MS HDPE Lined Non Return Valve:

Q: How should the MS HDPE Lined Non Return Valve be installed?

A: Install the valve horizontally, with the arrow on the valve body pointing in the direction of the process flow. Ensure that the flanged end connections match your pipe standards (ANSI, DIN, or BS) for a proper fit.Q: What are the main benefits of using this valve in corrosive chemical environments?

A: The HDPE lining and epoxy-coated MS body provide excellent resistance to acids and chemicals, extending service life while minimizing maintenance needs. The leak-proof, bubble-tight design also ensures safety and reliability during operation.Q: When is this valve type most suitable for use?

A: This non-return valve is ideal for applications involving corrosive chemicals, acids, or aggressive process fluids, particularly where reliable backflow prevention and low maintenance are essential.Q: Where can these valves be applied within industrial systems?

A: They are widely used in chemical processing plants, acid handling pipelines, wastewater treatment facilities, and any systems requiring safe handling of corrosive liquids or process fluids.Q: What is the process for operating this valve?

A: The valve operates manually; it automatically allows flow in one direction and prevents backflow through a swing-type disc mechanism. No additional power or actuation is required during operation.Q: What measures contribute to the valves long service life?

A: Key factors include the robust mild steel construction with HDPE lining, high-quality HDPE/PP disc, resilient HDPE lined seat, stainless steel pin, and epoxy-coated body, all designed for durability in harsh environments.Q: How does the valve ensure effective sealing and leak prevention?

A: The combination of a gasketed HDPE lining, resilient seat, and precision-engineered disc enables Class VI bubble-tight shutoff, ensuring there is no leakage when the valve is in the closed position.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lined Non Return Valves Category

MS PTFE Non Return Lined Valve

Minimum Order Quantity : 01 Unit

Control System : Manual

Port Size : Customizable from 25mm to 300mm

Application : Chemical, Pharmaceutical, Water Treatment Plants, Petrochemical Industries

Power : Manual

Connection Type : Flanged Ends

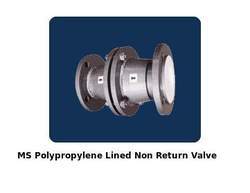

MS Polypropylene Lined Non Return Valve

Minimum Order Quantity : 01 Unit

Control System : Manual

Port Size : DN25 to DN200

Application : Chemical Processing, Water Treatment, Corrosive Fluid Handling

Power : Other, Manual/Nonpowered

Connection Type : Flanged

CS Ptfe Lined Non Return Valve

Minimum Order Quantity : 01 Unit

Control System : Manual/automatic closing based on flow direction

Port Size : Standard (DN25 to DN300 or as per requirement)

Application : Suitable for corrosive fluid handling, chemical process industries, pharmaceutical, and water treatment plants.

Power : Manual

Connection Type : Flanged ends as per ANSI B16.5 or DIN standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS